The valve body is lined with PTFE or PFA above 3mm, high permeation resistance. Vacuum-proof design with contract groove locking. Almost transparent, the best quality guaranteed

Pressure valve body material is available

Permanent body flange sealing is effective even under the most frequent thermal cycling conditions, the seal of the valve body has sufficient lining thickness, the labyrinth seal maximizes the contact area at the connector, and the valve body with a strong cup and cone structure can be properly positioned by itself.

Full-bore balls provide high CV values equal to pipes.

The reinforced PTFE seat provides permanent elastic bearing for the valve ball and ensures a seal tightness.

Anti-static: Any static build-up is eliminated due to the fact that the integral stem is equal to the body structure and elastic potential.

The integrated ball/stem design reduces the failure of the replacement valve ball and stem, and there is no stagnation, which is ideal

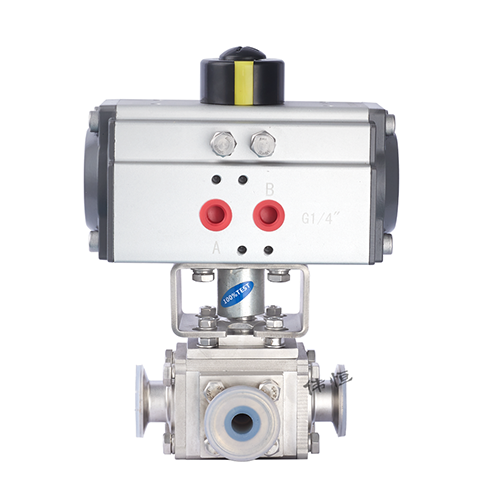

Pneumatic fluorine-lined Square tee ball valve is a special type of valve that combines pneumatic actuator and fluorine-lined technology, with the advantages of high efficiency, stability, and corrosion resistance.

The main feature of the Pneumatic Fluorine-Lined Square 3-Way Ball Valve is its square tee structure, which allows the valve to have higher flow control accuracy and stronger fluid adaptability. At the same time, fluorine-lined technology enables valves to have excellent corrosion resistance and can adapt to the transportation of various corrosive media.

Additionally, the introduction of pneumatic actuators allows valves to be controlled remotely and automated, enhancing production efficiency.

When installing and using pneumatic fluorine-lined square tee ball valves, the following points need to be noted:

Ensure that the valve is installed in the correct position and in accordance with the specified orientation.

Before use, the valve needs to be thoroughly inspected to ensure that it is intact.

During use, the valve needs to be regularly inspected and maintained to ensure its normal operation.

When operating the valve, it is necessary to follow the specified operating steps to avoid misoperation or damage to the valve.

Pneumatic fluorine-lined square tee ball valve is an important fluid control equipment that has been widely used in the industrial field. During use, it is necessary to pay attention to its installation and use requirements to ensure its normal operation and extend its service life.

Technical Scope

Temperature range: 0°C~150°C

Working Pressure: Vacuum ~16Mpa(20°C)

Applicable fluids: can convey extremely strong chemically corrosive media, can withstand high temperature, vacuum resistance, wear resistance, and can be anti-static.

Application field: used in injections, vaccines, food hygiene, beverages, pharmaceuticals, chemical chemicals, biology, lithium batteries, semiconductor engineering and other industries

Compliant with standards: Meets FDA and USP certifications.

Fluorine-lined valves, also known as fluoroplastic-lined

corrosion-resistant valves, are made of PTFE or PFA (or profiles

processed) by molding (or inlaying) on the inner wall of steel or iron

valve pressure bearings (the same method is applicable to the lining of

various pressure vessels and pipeline accessories) or the outer surface

of valve linings, and using its unique properties in strong corrosion

resistance media to make various valves and pressure vessels.

Fluorine-lined valves can use lining process for all the places that can be reached by the medium in the valve body, and the lining materials are generally made of fluoroplastics such as FEP (F46) and PCTFE (F3), which can be applied to various concentrations of sulfuric acid, hydrochloric acid, hydrofluoric acid, aqua regia and various organic acids, strong acids, strong oxidants and other corrosive media and other pipelines. However, fluorine-lined valves are limited by temperature, only suitable for mediums between -50°C~150°C, please consult our customer service for details.

Valves that can be made lined with fluorine plastics include: fluorine-lined butterfly valves,Fluorine-lined ball valves, fluorine-lined globe valve,Fluorine-lined diaphragm valves, fluorine-lined gate valves, fluorine-lined plug valves,Fluorine-lined pipe fittings、Fluorine-lined jointsetc., and accessories include (electric, pneumatic, electromagnetic, explosion-proof, filtering, adjustment, remote automatic control and other functions).

| Properties of PTFE-polytetrafluoroethylene | |

| High temperature resistance | The operating temperature is up to 250°C |

| Resistant to low temperatures | It has good mechanical toughness and maintains an elongation of 5% even when the temperature drops to -196°C |

| It is non-toxic | It has physiological inertness and has no adverse reactions as artificial blood vessels and organs implanted in the body for a long time |

| Mechanical properties | It is the smallest surface tension in solid materials, does not adhere to any substance, and its friction coefficient is extremely small, only 1/5 of polyethylene, which is an important feature of perfluorocarbon surfaces. Because the intermolecular force of the fluorocarbon-carbon chain is extremely low, PTFE is non-stick |

| Excellent insulation performance | A thick layer of newspaper film is enough to resist 1500V high voltage, |

| Chemical and weather resistance | Teflon is virtually immune to any chemical agents except molten alkali metals. For example, when boiled in concentrated sulfuric acid, nitric acid, hydrochloric acid, or even aqua regia, its weight and properties do not change, and it is almost insoluble in all solvents, and is only slightly soluble in perankanes (about 0.1g/100g) above 300°C. |

| Excellent weather resistance | It does not absorb moisture, is non-combustible, is extremely stable to oxygen and ultraviolet rays, and has the best aging life among plastics |

| Electrical performance | Teflon has low dielectric constant and dielectric loss over a wide frequency range, as well as high breakdown voltage, volumetric resistivity, and arc resistance |

| Model representation method | ||||||||||||

| WH | -600 | —Q1 | —C1 | —F | —16 | —P | —25 | —D1 | —B | —W2 | —B2 | —L |

| >1. Weiheng brand | >2. Drive mode | >3. Valve body type | >4. Connection method | >5. Sealing material | >6. Nominal pressure | >7. Valve body material | >8. Nominal diameter | >9. Control mode | >10. Explosion-proof level | —20~150℃ | >12. Accessory options | >13. Three flows |

| 1~7 mandatory options, 8~13 optional | ||||||||||||

| 1 codename | 5 codename | Sealed material | 10 code | Explosion-proof rating | |

| WH | Weiheng brand | F | PTFE | B | ExdIl BT4 Gb explosionproof and explosion-proof type |

| PPL | Para-polyphenylene | BZ | ExdllCT5 Gb explosion-proof and explosion-proof type | ||

| 2 codename | Drive mode | H | Metal hard seal | BC | Exdll CT6 Gb explosionproof and explosion-proof type |

| 600 | Pneumatic actuator series | Y | cemented carbide | BM | ExmbllT4 Gb cast explosion-proof type |

| 900 | Electric actuator system | X1 | Ding Qing rubber NBR | BA | Exiall CT6Ga intrinsically safe and explosion-proof |

| 2001 | Column plastic actuator angle seat valve series | X2 | Natural rubber NR | ||

| 2002 | Stainless steel actuator angle seat valve series | X3 | EPDM | 11 codenames | Medium temperature |

| X4 | Viton rubber FPM | W1 | -20-80C | ||

| 3 codename | Body type | X5 | Food grade silicone rubber SI | W2 | -20-150C |

| Q1 | Two-way valve | F46 | Fully lined polyperfluoroethylene FEP | W3 | -20-250C |

| Q2 | Three-way valve | PFA | Fully lined with soluble PTFE PFA | W4 | -29-425C |

| Q3 | Four-way valve | F4 | Fully lined PTFE | W5 | -29-650C |

| Q4 | Stationary ball valve | N | nylon | W6 | -196-60C |

| Q5 | V-ball | TC | Lined ceramic | ...... | ...... |

| Q6 | Low profile ball valve | J | Rubber lining | It has a special temperature that can be designed and manufactured according to customer requirements | |

| Q7 | Sanitary grade ball valves | PEEK | Polyether ether ketone | ||

| Q8 | Plastic ball valves | W | When the ring | 12 codenames | Accessory selection |

| Q9 | High Vacuum Ball Valve | ...... | ...... | B1 | 2-position, 3-way solenoid valve |

| Q10 | Fluorine ball valve in the whole village | Other special sealing materials can be designed and manufactured according to customer requirements | B2 | 2-position 5-way solenoid valve | |

| Q11 | Cryogenic ball valves | B3 | 2-position 3-way explosion-proof solenoid valve | ||

| Q12 | Insulated ball valve | 6 codename | Nominal pressure | B4 | 2-position 5-way explosion-proof solenoid valve |

| Q13 | Eccentric hemispherical valve | ...... | ...... | B5 | Filter pressure reducing valve |

| Q14 | Tank bottom valve | B6 | Limit switch | ||

| Q15 | Ceramic ball valves | 7 codename | Body material | B7 | Explosion-proof limit switch |

| D1 | Centerline soft-sealed butterfly valve | Q | Ductile iron HT200 | B8 | Hand manipulation mechanism |

| D2 | 3. Eccentric butterfly valve | C | carbon steel | B9 | Locator |

| D3 | Sanitary Butterfly Valve | P | Stainless steel 304 | ...... | ...... |

| D4 | Plastic butterfly valve | R | Stainless steel 316 | ||

| D5 | Ventilation butterfly valve | PL | Stainless steel 304L | 13 codenames | Three flows |

| D6 | Fluorine butterfly valve in the whole village | RL | Stainless steel 316L | L | Tee L-type BC switching |

| D7 | High vacuum butterfly valve | U | PVC UPVC | T1 | Tee T-type C-port switch |

| D8 | Powder butterfly valve | PP | Reinforced polypropylene RPP | T2 | Tee T-type AB switching |

| Z1 | Gate valve | L | Aluminum alloy | T3 | Tee T-type AC switching |

| Z2 | Knife gate valve | ...... | ...... | T4 | Tee T-type B-port switch |

| J1 | Globe valve | Other special valve body materials can be designed and manufactured according to customer requirements | |||

| J2 | Bellows cut stop valve | ||||

| J3 | Angle seat valve | 8 codename | It is called the path | ||

| F1 | Upward expansion discharge valve | ...... | ...... | ||

| F2 | Downward discharge valve | ||||

| Other special valve body materials can be designed and manufactured according to customer requirements | 9 code | Control mode | |||

| Z | Standard switch type | ||||

| 4 codenames | Connection | T1 | Integral switching type | ||

| C1 | Female thread | T2 | Overall adjustment | ||

| C2 | By order | T3 | RS485 bus type | ||

| C3 | Male thread | D1 | Double acting | ||

| C4 | flange | D2 | Double-acting adjustment type | ||

| C5 | KF vacuum chuck | E1 | Uni-acting normally closed | ||

| C6 | weld | E2 | Single-acting normally closed regulation type | ||

| C7 | Pair clip | E3 | Single-acting and always open | ||

| C8 | Clamps | E4 | Single-acting normally open adjustment type | ||

Pneumatic Fluorine-Lined Square tee ball valve: An Essential Solution for Corrosive Fluid Control

A Pneumatic Fluorine-Lined Square Tee Ball Valve is a vital component in industries that handle corrosive fluids, gases, or chemicals. These valves are designed to manage flow control in systems that require high resistance to chemical attacks, high temperatures, and pressure. Featuring a fluorine-based lining, this valve ensures superior performance in highly corrosive environments, such as the chemical processing, pharmaceutical, and oil industries.

The integration of a pneumatic actuator provides automated and precise control, making the Pneumatic Fluorine-Lined Square Tee Ball Valve an ideal choice for automated systems where minimal human intervention is needed.

The fluorine-lined coating offers unparalleled resistance to aggressive chemicals, acids, and solvents. This makes the valve particularly suitable for industries where traditional materials would degrade quickly, such as the chemical and petrochemical sectors.

With pneumatic actuation, this valve offers quick response times, precise flow control, and reliable sealing. It’s engineered to handle a range of pressures, making it perfect for both low and high-pressure systems.

The fluorine lining is non-reactive to most corrosive materials, extending the valve’s service life and reducing maintenance needs.

Pneumatic operation is energy-efficient compared to electric actuation systems, providing a low-maintenance solution that reduces operational costs.

The square tee design provides optimal space utilization, allowing for easy integration into compact systems where space is limited.

| Specification | Value |

|---|---|

| Valve Type | Pneumatic Ball Valve |

| Body Material | Carbon Steel, Stainless Steel |

| Lining Material | Fluoropolymer (e.g., PTFE) |

| Pressure Range | 0.5 to 20 MPa |

| Temperature Range | -20°C to 150°C |

| Size Range | ½ inch to 8 inches |

| Connection Type | Flanged, Threaded |

| Actuation Type | Pneumatic |

| Application | Chemical Processing, Petrochemical, Food & Beverage |

| End Connection | Butt Weld, Socket Weld, Threaded |

The Pneumatic Fluorine-Lined Square Tee Ball Valve operates via pneumatic actuation, which uses compressed air to move the valve mechanism. Here’s a step-by-step guide for operation:

Ensure the system is depressurized before installing the valve.

Inspect the valve for any shipping damage, ensuring that the fluorine lining is intact.

Check actuator settings to ensure that the pneumatic system is operating within the recommended air pressure range.

When air is supplied to the pneumatic actuator, it drives the ball valve to either open or close, controlling the flow of the fluid.

Air pressure typically ranges from 4 to 8 bar. Ensure that the air supply is clean, dry, and filtered.

The square tee design allows for the precise control of flow from three different directions. The valve can redirect fluids to different branches, offering versatility in process control.

The pneumatic actuator enables quick response times, ensuring optimal performance in high-demand applications.

In the event of a system failure or an emergency, the pneumatic actuator can be triggered to shut the valve off, ensuring system safety.

Regular maintenance is critical to ensuring the longevity and optimal performance of the Pneumatic Fluorine-Lined Square Tee Ball Valve. Below is a guide for routine maintenance tasks:

Inspect the fluorine lining for signs of damage or wear, especially in areas exposed to high-pressure and highly corrosive fluids.

Check the pneumatic actuator for any air leaks. Ensure that all seals and gaskets are intact.

Test the valve for smooth operation. If there is any resistance when actuating, it may indicate internal contamination or mechanical issues.

Valve Body: Clean the valve body using non-abrasive cleaners to avoid damaging the fluorine lining.

Pneumatic Actuator: Periodically clean the actuator air inlet and exhaust to remove dust and debris that could cause blockage or poor performance.

Use a soft cloth to wipe down the valve components and ensure no chemical buildup.

Lubricate the actuator’s moving parts periodically using a compatible lubricant. This ensures smooth operation and reduces wear on the pneumatic components.

Over time, seals and gaskets may degrade due to exposure to harsh chemicals. It’s essential to inspect and replace these components as part of the regular maintenance schedule.

Functional Testing: Regularly test the valve’s opening and closing operation. The valve should fully open and close without resistance or leakage.

Leak Testing: Perform pressure testing to ensure no leakage occurs at the valve seat or connections.

Actuator Performance: Verify that the pneumatic actuator responds correctly to changes in air pressure.

When testing the Pneumatic Fluorine-Lined Square Tee Ball Valve, ensure compliance with relevant industry standards, such as ISO 9001 for quality management and API 6D for valve specifications.

Inspect the body and lining for cracks, corrosion, or physical damage.

Ensure that the actuator is securely attached and free of visible damage.

Perform a hydrostatic pressure test to ensure the valve can withstand the operating pressure without any leakage.

Test at both maximum and minimum pressure points to ensure reliable performance.

A seat leakage test should be performed to check the integrity of the valve’s sealing mechanism.

Use helium or another suitable tracer gas to identify any leakage points.

Perform regular cycle tests to verify that the valve can open and close multiple times without failure. This is particularly important for high-cycle applications.

The Pneumatic Fluorine-Lined Square Tee Ball Valve is a reliable and efficient solution for controlling fluid flow in harsh, corrosive environments. It combines the benefits of fluorine’s chemical resistance with the precision and speed of pneumatic actuation. Its robust design ensures minimal downtime, reduced maintenance costs, and long service life.

Whether for chemical processing, petrochemical, or other industrial applications, this valve offers the performance, durability, and versatility you need. For industries handling aggressive fluids or gases, the Pneumatic Fluorine-Lined Square Tee Ball Valve is an indispensable tool in ensuring smooth, safe, and efficient operations.

RELATED

RELATED

Tel: +86 577 8699 9257

Tel: +86 135 8786 5766 /+86 137 32079372

Email: wzweiheng@163.com

Address:No. 1633, Yidaoba Road, Binhai Industrial Park, Wenzhou City, Zhejiang Province

Scan wechat

This website uses cookies to ensure you get the best experience on our website.