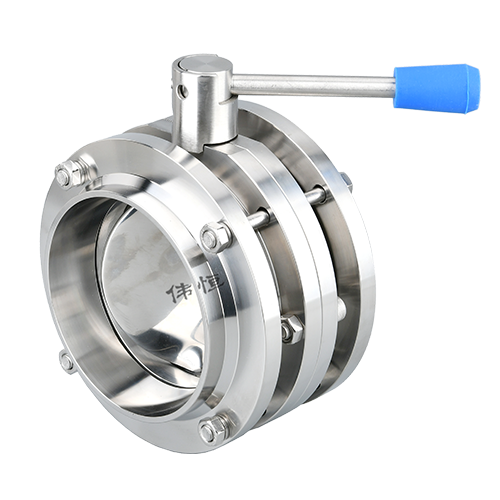

Sanitary three-piece pull handle Welded Butterfly Valve is a valve with a complex structure, which is characterized by a three-piece structure and high sealing performance and stability. At the same time, the valve adopts a pull-handle design, which is more convenient and labor-saving to operate.

Sanitary three-piece pull handle welded butterfly valves are usually used in some high-pressure and high-temperature occasions, such as in pipeline systems in petroleum, chemical, electric power and other industries. Due to its complex structure, it requires regular maintenance and maintenance to ensure its normal performance.

The sanitary three-piece pull handle welded butterfly valve is a valve with excellent performance and easy operation, suitable for a variety of different working conditions. If you need to know more about this valve, you can consult relevant professionals or consult relevant technical information.

| Model representation method | ||||||||||||

| WH | -600 | —Q1 | —C1 | —F | —16 | —P | —25 | —D1 | —B | —W2 | —B2 | —L |

| >1. Weiheng brand | >2. Drive mode | >3. Valve body type | >4. Connection method | >5. Sealing material | >6. Nominal pressure | >7. Valve body material | >8. Nominal diameter | >9. Control mode | >10. Explosion-proof level | —20~150℃ | >12. Accessory options | >13. Three flows |

| 1~7 mandatory options, 8~13 optional | ||||||||||||

| 1 codename | 5 codename | Sealed material | 10 code | Explosion-proof rating | |

| WH | Weiheng brand | F | PTFE | B | ExdIl BT4 Gb explosionproof and explosion-proof type |

| PPL | Para-polyphenylene | BZ | ExdllCT5 Gb explosion-proof and explosion-proof type | ||

| 2 codename | Drive mode | H | Metal hard seal | BC | Exdll CT6 Gb explosionproof and explosion-proof type |

| 600 | Pneumatic actuator series | Y | cemented carbide | BM | ExmbllT4 Gb cast explosion-proof type |

| 900 | Electric actuator system | X1 | Ding Qing rubber NBR | BA | Exiall CT6Ga intrinsically safe and explosion-proof |

| 2001 | Column plastic actuator angle seat valve series | X2 | Natural rubber NR | ||

| 2002 | Stainless steel actuator angle seat valve series | X3 | EPDM | 11 codenames | Medium temperature |

| X4 | Viton rubber FPM | W1 | -20-80C | ||

| 3 codename | Body type | X5 | Food grade silicone rubber SI | W2 | -20-150C |

| Q1 | Two-way valve | F46 | Fully lined polyperfluoroethylene FEP | W3 | -20-250C |

| Q2 | Three-way valve | PFA | Fully lined with soluble PTFE PFA | W4 | -29-425C |

| Q3 | Four-way valve | F4 | Fully lined PTFE | W5 | -29-650C |

| Q4 | Stationary ball valve | N | nylon | W6 | -196-60C |

| Q5 | V-ball | TC | Lined ceramic | ...... | ...... |

| Q6 | Low profile ball valve | J | Rubber lining | It has a special temperature that can be designed and manufactured according to customer requirements | |

| Q7 | Sanitary grade ball valves | PEEK | Polyether ether ketone | ||

| Q8 | Plastic ball valves | W | When the ring | 12 codenames | Accessory selection |

| Q9 | High Vacuum Ball Valve | ...... | ...... | B1 | 2-position, 3-way solenoid valve |

| Q10 | Fluorine ball valve in the whole village | Other special sealing materials can be designed and manufactured according to customer requirements | B2 | 2-position 5-way solenoid valve | |

| Q11 | Cryogenic ball valves | B3 | 2-position 3-way explosion-proof solenoid valve | ||

| Q12 | Insulated ball valve | 6 codename | Nominal pressure | B4 | 2-position 5-way explosion-proof solenoid valve |

| Q13 | Eccentric hemispherical valve | ...... | ...... | B5 | Filter pressure reducing valve |

| Q14 | Tank bottom valve | B6 | Limit switch | ||

| Q15 | Ceramic ball valves | 7 codename | Body material | B7 | Explosion-proof limit switch |

| D1 | Centerline soft-sealed butterfly valve | Q | Ductile iron HT200 | B8 | Hand manipulation mechanism |

| D2 | 3. Eccentric butterfly valve | C | carbon steel | B9 | Locator |

| D3 | Sanitary Butterfly Valve | P | Stainless steel 304 | ...... | ...... |

| D4 | Plastic butterfly valve | R | Stainless steel 316 | ||

| D5 | Ventilation butterfly valve | PL | Stainless steel 304L | 13 codenames | Three flows |

| D6 | Fluorine butterfly valve in the whole village | RL | Stainless steel 316L | L | Tee L-type BC switching |

| D7 | High vacuum butterfly valve | U | PVC UPVC | T1 | Tee T-type C-port switch |

| D8 | Powder butterfly valve | PP | Reinforced polypropylene RPP | T2 | Tee T-type AB switching |

| Z1 | Gate valve | L | Aluminum alloy | T3 | Tee T-type AC switching |

| Z2 | Knife gate valve | ...... | ...... | T4 | Tee T-type B-port switch |

| J1 | Globe valve | Other special valve body materials can be designed and manufactured according to customer requirements | |||

| J2 | Bellows cut stop valve | ||||

| J3 | Angle seat valve | 8 codename | It is called the path | ||

| F1 | Upward expansion discharge valve | ...... | ...... | ||

| F2 | Downward discharge valve | ||||

| Other special valve body materials can be designed and manufactured according to customer requirements | 9 code | Control mode | |||

| Z | Standard switch type | ||||

| 4 codenames | Connection | T1 | Integral switching type | ||

| C1 | Female thread | T2 | Overall adjustment | ||

| C2 | By order | T3 | RS485 bus type | ||

| C3 | Male thread | D1 | Double acting | ||

| C4 | flange | D2 | Double-acting adjustment type | ||

| C5 | KF vacuum chuck | E1 | Uni-acting normally closed | ||

| C6 | weld | E2 | Single-acting normally closed regulation type | ||

| C7 | Pair clip | E3 | Single-acting and always open | ||

| C8 | Clamps | E4 | Single-acting normally open adjustment type | ||

The Sanitary Three-Piece Pull Handle Welded Butterfly Valve is an essential component in fluid control systems, designed for industries requiring high standards of hygiene and durability. Commonly used in food processing, pharmaceuticals, biotechnology, and other sanitary applications, this valve ensures efficient and reliable operation while maintaining strict hygienic conditions. With its three-piece welded construction, the valve offers ease of maintenance and long-term performance.

This comprehensive guide provides a detailed overview of the Sanitary Three-Piece Pull Handle Welded Butterfly Valve, covering its operating instructions, environmental standards, after-sales service, and packaging information. This guide is optimized to meet Google SEO standards, making it informative, clear, and structured for better visibility in search results.

The Sanitary Three-Piece Pull Handle Welded Butterfly Valve is designed for the precise control of fluid flow in sanitary systems. Its three-piece design allows for easy installation, disassembly, and maintenance, while its welded construction provides superior strength and leak-proof performance. The valve’s pull handle operation ensures smooth and easy control, making it ideal for systems requiring manual regulation of fluid flow.

Three-Piece Design: The valve consists of three components (body, disc, and handle), which are easy to assemble, disassemble, and clean. This design ensures maximum flexibility for installation and maintenance.

Welded Construction: Provides additional strength, durability, and resistance to leaks, making it suitable for high-pressure systems.

Hygienic and Corrosion-Resistant: Constructed from 304 or 316L stainless steel, offering excellent resistance to corrosion and ensuring long-term performance in aggressive environments.

FDA, 3A, and EHEDG Compliant: Meets the stringent hygiene standards required in food, beverage, and pharmaceutical industries.

Pull Handle Operation: Allows for easy manual operation, providing precise control over the valve's opening and closing.

Food and Beverage: Ideal for controlling the flow of liquids in food processing systems, such as beverages, dairy products, and syrups.

Pharmaceuticals: Used in pharmaceutical production systems to control the flow of sterile liquids and chemicals.

Biotechnology: Suitable for laboratory and production systems where sanitary conditions are critical.

Cosmetic Manufacturing: Ensures hygienic control of liquid ingredients in cosmetic production lines.

The Sanitary Three-Piece Pull Handle Welded Butterfly Valve is designed to be easy to operate and maintain. Below are the operating instructions to ensure the valve functions properly throughout its lifecycle.

Preparation: Ensure the valve is compatible with your pipeline by selecting the correct size and end connection type (flanged, tri-clamp, or threaded).

Installation Process:

Ensure that the system is shut down and depressurized before installation.

Align the valve with the pipe flanges or connections and tighten the bolts evenly to avoid damaging the sealing surfaces.

For a tri-clamp installation, ensure the clamp is securely tightened without over-tightening, which could damage the gaskets.

Inspect the valve for proper alignment and ensure that the handle is easy to operate.

Opening and Closing: The valve is operated manually by rotating the pull handle. Turn the handle in a clockwise direction to close the valve and counterclockwise to open it.

Flow Control: The valve offers precise flow control, which is ideal for regulating the flow of liquids or powders. Ensure that the valve is fully opened or closed to prevent leakage or system inefficiencies.

Pressure and Temperature Limits: Operate the valve within the recommended pressure (up to 10 bar) and temperature (up to 150°C) limits to prevent damage to the valve body, seals, or gaskets.

Clean-In-Place (CIP): For hygienic industries like food and pharmaceuticals, it is recommended to use CIP systems to clean the valve. CIP systems allow for automated cleaning without disassembling the valve.

Manual Cleaning: If manual cleaning is required, disassemble the valve, inspect for any wear, clean the internal components with a non-abrasive cleaning solution, and reassemble the valve.

Seal Inspection: Periodically check the seals and gaskets for wear and replace them as needed to maintain a leak-proof seal.

The Sanitary Three-Piece Pull Handle Welded Butterfly Valve is designed to meet global environmental standards, ensuring minimal impact on the environment while maintaining high performance in sanitary applications.

FDA Compliant: The valve meets the standards required for equipment that comes into contact with food, ensuring that no harmful materials leach into the fluids being processed.

3A Sanitary Standards: The valve is compliant with 3A sanitary standards, which set requirements for hygienic equipment in dairy and food processing systems.

EHEDG Certification: The valve meets EHEDG standards for hygienic design and ensures safe handling of products in critical industries like pharmaceuticals and food processing.

Material Sustainability: The valve is made from 304 or 316L stainless steel, which is both durable and recyclable, reducing the environmental impact.

Energy Efficiency: The valve is designed to operate with low resistance to fluid flow, reducing the energy consumption of pumping systems.

Long Lifespan: The valve’s durable construction ensures a long service life, minimizing the need for frequent replacements and reducing overall waste.

After the valve has reached the end of its lifecycle, it should be disposed of according to local environmental regulations. Stainless steel components can be recycled, contributing to sustainability efforts.

We offer comprehensive after-sales service to ensure the Sanitary Three-Piece Pull Handle Welded Butterfly Valve continues to perform optimally throughout its lifespan. Here are the details of our after-sales service:

Warranty Period: The valve comes with a 12-month warranty from the date of purchase, covering defects in material and workmanship under normal usage conditions.

Coverage: The warranty covers any defects related to manufacturing, such as faulty materials or assembly errors.

Exclusions: The warranty does not cover damage caused by improper installation, misuse, or failure to follow cleaning and maintenance instructions.

24/7 Support: Our technical support team is available 24/7 to assist with installation, troubleshooting, and operational inquiries.

On-Site Assistance: If required, we provide on-site service for complex installations or repairs.

Maintenance Training: We offer training sessions for your team on proper valve installation, operation, and maintenance to ensure optimal performance.

Genuine Parts: Only genuine parts should be used for repairs and maintenance. We offer a full range of replacement seals, gaskets, and other components to ensure continued performance.

Availability: Replacement parts are available through our online store and can be shipped to your location as required.

The Sanitary Three-Piece Pull Handle Welded Butterfly Valve is packaged to ensure it arrives in perfect condition, ready for installation and use.

Inner Packaging: Each valve is individually wrapped in bubble wrap or foam to prevent any damage during shipping.

Outer Packaging: The valve is placed in a corrugated cardboard box for protection. For larger quantities, the valves are packed in wooden crates to avoid crushing or deformation.

Labeling: Each package includes clear labeling with product information, such as valve type, size, and model number, along with relevant certification marks (e.g., FDA, EHEDG).

Domestic and International: We offer both domestic and international shipping via standard freight, air freight, or express courier depending on your needs.

Customs Documentation: All necessary customs documentation is provided for international shipments, including product certifications and invoice details.

The Sanitary Three-Piece Pull Handle Welded Butterfly Valve offers unmatched performance and reliability for industries requiring stringent hygienic conditions. Its three-piece design allows for easy disassembly and maintenance, while its welded construction provides exceptional strength and leak-proof reliability. Compliant with key standards such as FDA, 3A, and EHEDG, this valve is ideal for food processing, pharmaceuticals, and biotechnology.

With clear operating instructions, environmental compliance, comprehensive after-sales support, and secure packaging, the Sanitary Three-Piece Pull Handle Welded Butterfly Valve is designed to meet the high standards required for sanitary fluid control systems.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Tel: +86 577 8699 9257

Tel: +86 135 8786 5766 /+86 137 32079372

Email: wzweiheng@163.com

Address:No. 1633, Yidaoba Road, Binhai Industrial Park, Wenzhou City, Zhejiang Province

Scan wechat

This website uses cookies to ensure you get the best experience on our website.